Thermal Monitoring Drone

Description:

CAD designs and Arduino circuits for a drone. CAD designs, circuits, and Raspberry Pi program for an embedded system that detects cable presence, captures thermal images, and detects temperature spikes.

I am Ecuadorian, Mechatronic Engineer passionate about the technological world and with it the possibility of being part of it creating my own projects.

I have skills and experience related to 3D design, web and application programming, data analysis, data science, and embedded systems development. Able to work and learn autonomously, predisposed to work in multidisciplinary teams to share, improve or learn various knowledge.

CAD designs and Arduino circuits for a drone. CAD designs, circuits, and Raspberry Pi program for an embedded system that detects cable presence, captures thermal images, and detects temperature spikes.

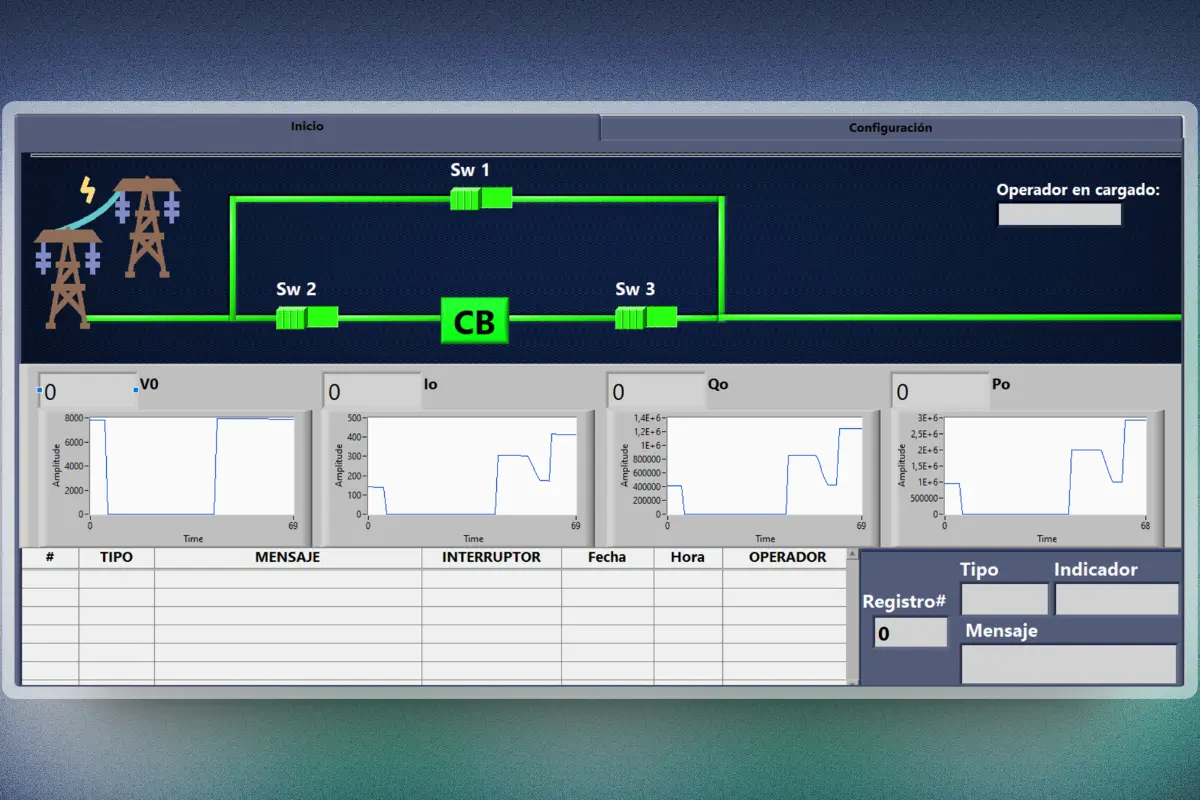

Real-time circuit simulation, connected via OPC to a LABVIEW interface, for monitoring and control.

Design of a pump system in Proteus, controlled by an Atmega328p, and visualization in Ubidots of the system's status communicated by a program developed in Python.

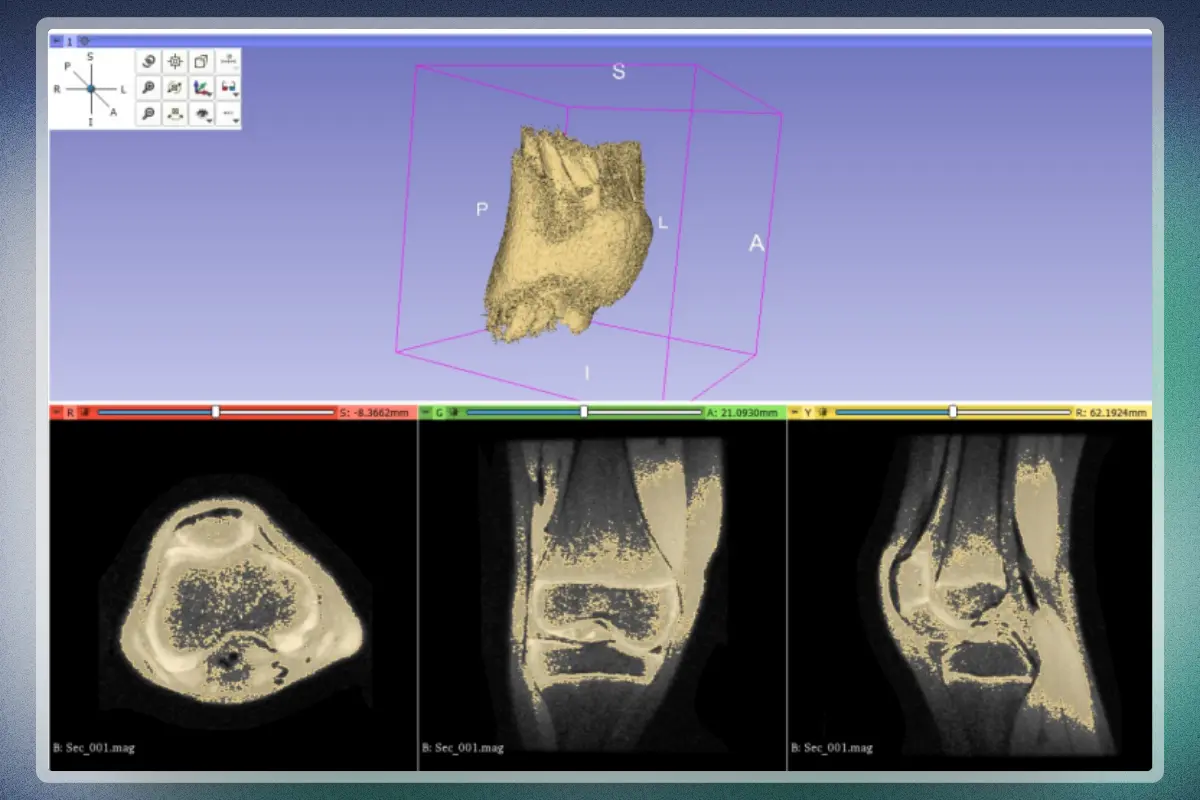

3D design of a knee and editing of a total knee prosthesis, using Slice 3D and Blender software to adapt the existing knee prosthesis to the test knee.

Design of an HMI for the control of a pump system, which has three pumps. Two pumps are primary and the third is backup in case one fails or is disabled for maintenance. Each pump has its start and stop pushbuttons, as well as its enable or disable selector. The system will have manual and automatic operation commanded by the signal sent by a selector.

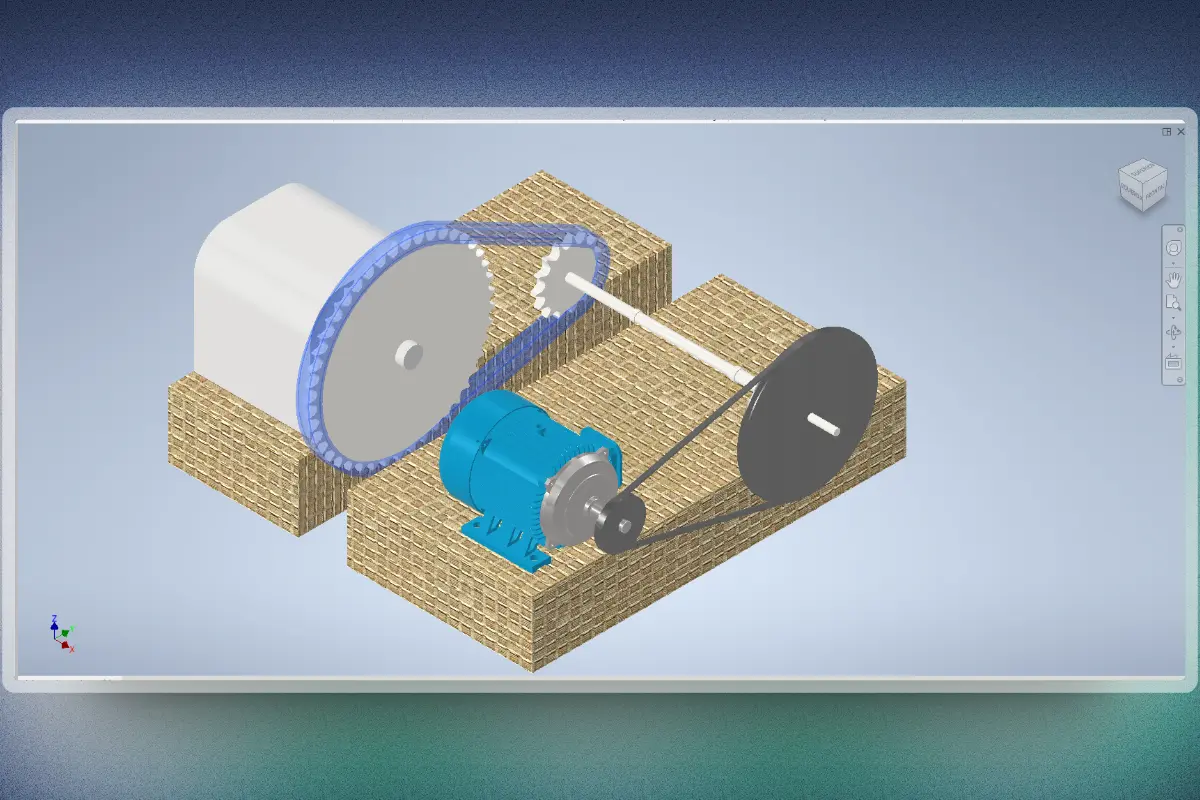

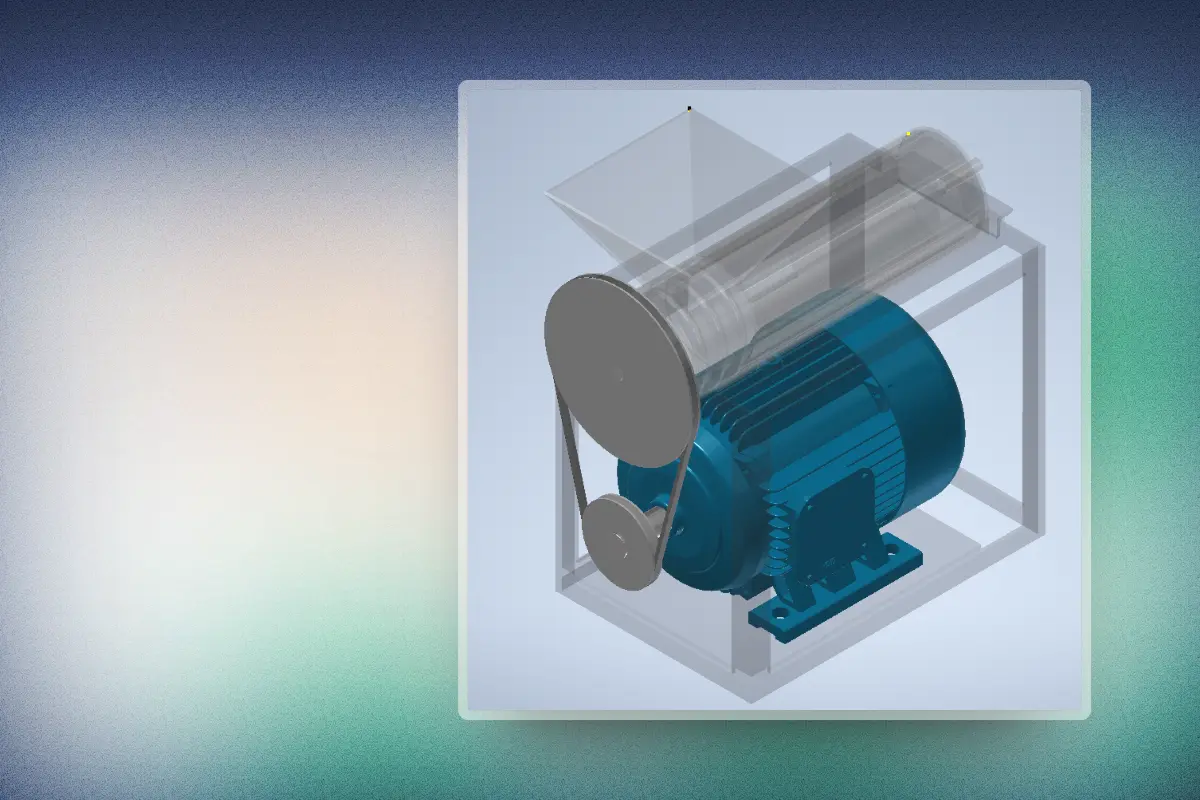

A mechanism is designed where the shaft of a mill receives the necessary power and speed through pulley-chains. In turn, the shaft that transmits power to the pulley with chain receives the input power through a set of V-belt pulleys, as well as being supported by 2 bearings.

Design and feasibility analysis of a rice stacker using renewable energy for implementation in a developing agricultural community.

Automatic pet feeder project controlled by a mobile application that allows scheduling feeding times.

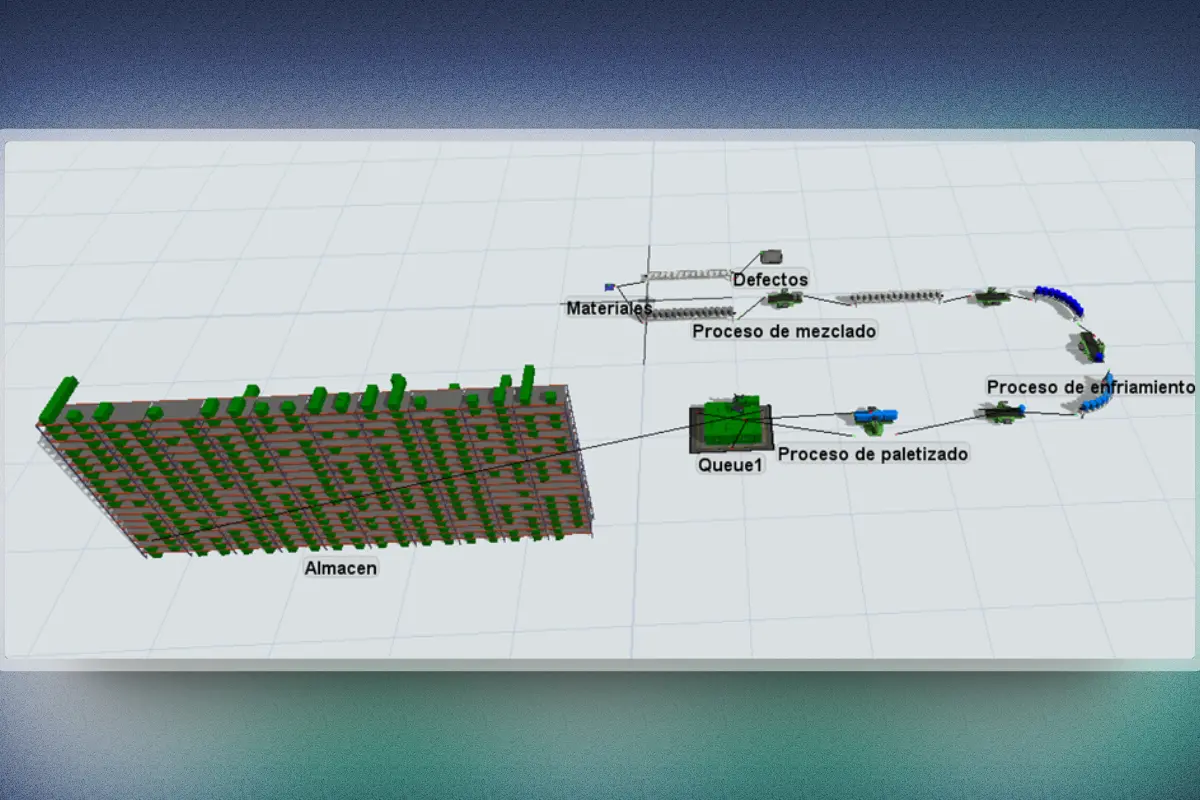

Redesigning the bottle manufacturing system of a company to reduce production times, increase system flexibility, and improve company profitability.

Objective:

Improve sugar production quality system by modifying manufacturing stages to avoid frequent product rejection upon delivery.

Issue:

A sugar-producing plant consists of several stages containing certain processes that make production efficient:

*Crystallization

*Juice delivery and extraction

*Evaporation

*Juice purification

The plant lacks sugar quality controls, so customers want quality tests based on random sampling so that if the product passes the tests, the order is accepted; otherwise, the product will be returned in full regardless of the order size.

doi: 10.1109/FNWF55208.2022.00048.

R. Estrada, V. Asanza, D. Torres, I. Valeriano and D. Alvarado